Every building tells two stories: the one the architect designed, and the one that was actually constructed. Over time, small field adjustments, tight installation spaces, last-minute design changes, and undocumented modifications create real-world conditions that no original plan fully reflects. This gap is why so many construction and renovation projects run into delays, clashes, and unexpected costs. And it’s also why 3D laser scanning has become one of the most reliable tools for capturing true, measurable as-built conditions—making projects faster, safer, and far more predictable.

What Are As-Built Drawings?

As-built drawings are the final record of a structure as it exists today, not the version shown in the design phase. They document: Actual field measurements

- Final MEP routing

- Structural variations

- Installation changes

- Site-driven modifications

Accurate as-builts are essential for renovations, facility operations, maintenance planning, and long-term asset management.

What Are Original Plans (Design Intent Documents)?

Original plans describe the architect’s or engineer’s vision before construction begins. They include:

- Proposed layouts

- Intended structural details

- Planned MEP locations

- Design expectations and specifications

These documents represent the blueprint of the ideal project, but rarely match the real-world outcome.

Why the Difference Between As-Builts and Original Plans Is Important

The discrepancies between “design intent” and “built reality” aren’t harmless, they directly impact cost, safety, scheduling, and constructability.

Impact on Construction

Field teams often discover conditions that contradict the drawings, forcing expensive redesigns or change orders.

Impact on Renovations

Renovation projects rely heavily on knowing what’s behind walls, ceilings, and slabs. If drawings are wrong, the entire project can stall.

Impact on Safety and Compliance

Incorrect routing of fire protection, electrical systems, or load-bearing elements can create major safety and code compliance risks.

Impact on Budgets

Unexpected discoveries lead to unplanned labor, rework, delayed inspections, and increased material costs.

This is why accurate as-builts are no longer optional, they’re a foundational requirement for every modern AEC workflow.

Key Differences: As-Built Drawings vs. Original Plans (Table)

| Category | Original Plans (Design Intent) | As-Built Drawings (Field Reality) |

|---|---|---|

| Purpose | Shows the intended design before construction begins | Shows the actual built conditions after construction |

| Source of Data | Created by architects & engineers during design | Captured on-site using measurements, photos, or 3D laser scanning |

| Accuracy Level | Idealized and theoretical | High accuracy (especially with 3D laser scanning) |

| Reflects Changes? | Does not include field changes, improvisations, or deviations | Includes all adjustments, modifications, & real-world conditions |

| Used For | Permits, bidding, initial construction planning | Renovations, facility management, clash detection, maintenance |

| MEP (Mechanical/Electrical/Plumbing) | Shown as intended routing | Shows actual pipe runs, conduit paths, and duct placement |

| Structural Elements | Designed beam/column positions | Reflects actual placement, shifts, or construction tolerances |

| Dimensions | Based on design assumptions | Verified site measurements, often with mm-level accuracy |

| Accuracy Over Time | Becomes outdated once construction starts | Remains the most accurate reference until a remodel occurs |

| Risk of Rework | High—because assumptions may not match reality | Low—because it reflects real site conditions |

| Creation Method | CAD/Revit based on designer inputs | Traditionally measured manually, now mostly via LiDAR scanning |

| Cost Impact | Cheaper to produce but can cause costly errors later | Higher upfront cost but huge savings in rework & delays |

| Role in Digital Twins | Not suitable for digital twin creation | Ideal foundation for digital twins & BIM workflows |

| Use in Prefabrication | Limited reliability | Highly reliable for off-site prefabrication & coordination |

Why As-Builts Rarely Match the Original Plans

There are many reasons buildings deviate from their original design.

Field-Driven Adjustments

Installers must often modify component locations based on space constraints or real-world alignment.

Contractor Modifications

Subcontractors frequently reroute ductwork, piping, and conduits to accommodate equipment, access, or coordination issues.

Human Error

Not all field changes get documented, and many red-line drawings never make it back to the design team.

Material or Design Substitutions

Different equipment sizes or last-minute design shifts can alter dimensions significantly.

Even a one-inch deviation can create major issues when coordinating MEP, structural, and architectural systems.

Common Problems Caused by Inaccurate As-Builts

When teams rely on outdated drawings, they often encounter:

- Costly rework due to unforeseen obstructions

- MEP clashes during fabrication or installation

- Renovation delays while re-measuring the site

- Safety hazards from unknown utilities or structural elements

These issues are preventable with proper documentation.

How 3D Laser Scanning Captures True As-Built Conditions

3D laser scanning, or LiDAR scanning, is the fastest and most accurate way to document any environment.

Laser scanners measure millions of data points per second, capturing exact geometry with millimeter precision.

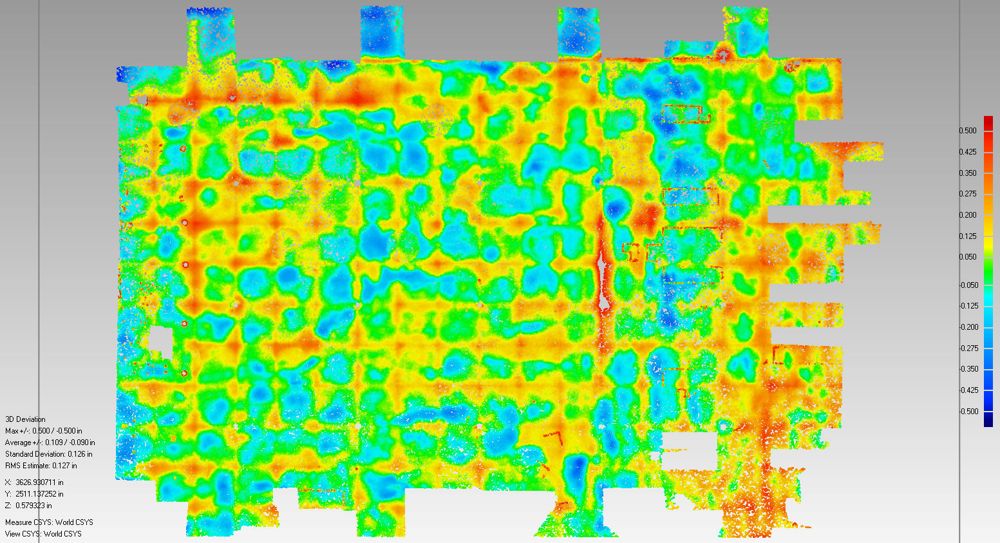

Point Cloud Output

All measurements are combined into a single dataset a “point cloud” that represents the entire space in 3D.

High Accuracy Levels

Professional scanners (Leica RTC360, Faro Focus, etc.) deliver:

- ±2 mm accuracy

- Highly detailed geometry

- Colorized scan data

- 360° environmental capture

This eliminates guesswork and provides a digital record of the facility as it truly exists.

3D Laser Scanned As-Builts vs. Original Plans: Key Differences

Once scanning is complete, teams quickly see discrepancies such as:

Geometry Variations

Walls, windows, and structural members may not align perfectly as shown in the drawings.

Dimensional Differences

Ceiling heights, slab elevations, and floor flatness vary significantly between design and reality.

MEP Routing Changes

HVAC ducts, electrical conduits, and plumbing systems frequently shift during installation.

Structural Offsets

Columns and beams can be out of alignment by inches enough to disrupt prefabrication or equipment placement.

Laser scanning exposes these differences before they cause problems.

As-Built vs. Original Plans: Cost Implications

The financial impact of inaccurate drawings is enormous especially on renovations and complex facilities.

Cost of Errors

Contractors often discover unforeseen conditions mid-project, leading to redesigns and change orders.

Cost of Rework

Rework typically adds 5–15% to project budgets.

Cost of Delays

Schedule overruns increase labor, rental equipment, and overhead expenses.

Savings With 3D Laser Scanning

By starting with accurate conditions, companies save money on:

- Clash-related rework

- Fabrication changes

- Field verification

- Safety and compliance issues

Many organizations report 30–50% project savings when using laser-scanned as-builts.

(Internal linking opportunity: link to Scan to BIM Services for Revit modeling and coordination.)

Benefits of Using 3D Laser Scanning for As-Built Verification

3D scanning provides advantages that manual measurements and traditional surveys simply can’t match.

Exceptional Accuracy

Millimeter-level precision eliminates measuring errors.

Faster Project Kickoff

Design teams can begin modeling or renovation planning immediately.

Early Clash Detection

Scans reveal conflicts before construction ever begins.

Digital Twin Capabilities

The entire facility can be viewed virtually for planning, inspections, and asset management.

Laser scanning supports BIM, prefabrication, and digital workflows used across the AEC industry.

Industries That Rely on As-Built Scanning

Accurate as-builts matter across multiple sectors:

- Construction – renovations, tenant improvements, new builds

- Oil & Gas – refineries, compressor stations, process plants

- Manufacturing – equipment relocation and plant upgrades

- Commercial Real Estate – office buildings, hotels, retail sites

- Historic Preservation – museums, monuments, heritage sites

Case Studies (Optional Section)

You can highlight:

- A refinery where scanning prevented a major piping collision

- A school renovation requiring precise slab elevation mapping

- A museum where scanning protected fragile architectural elements

If you’d like, I can write customized case studies for Arrival 3D’s portfolio.

How Facility Managers, Engineers & Architects Use the Data

With accurate as-builts, teams can:

- Validate existing conditions

- Plan equipment upgrades

- Coordinate MEP systems

- Improve asset documentation

- Create BIM models for long-term operations

This improves efficiency, reduces risk, and increases the accuracy of every future project.

Deliverables From a 3D Laser Scanning Project

A complete scanning package typically includes:

- Point Clouds (.RCP, .E57, .LAS)

- 2D CAD drawings (floor plans, elevations, sections)

- Revit BIM models (LOD 200–500)

- TruView or 360° virtual walkthroughs

- Deviation or QA/QC analysis reports

These deliverables become the foundation for design, coordination, and construction.

Choosing the Right 3D Laser Scanning Company

A reliable scanning partner should have:

- High-end LiDAR equipment

- Skilled field technicians

- Strong BIM/Revit modeling capabilities

- Fast turnaround times

- Nationwide availability

- Clear and transparent pricing

Conclusion: Accurate As-Builts Start With Reality Capture

Original plans show what was supposed to be built. As-builts show what actually exists.

Laser scanning bridges the gap bringing clarity, accuracy, and confidence to every decision that follows. Whether you’re planning a renovation, coordinating MEP systems, or managing a complex facility, accurate 3D as-builts reduce surprises, eliminate rework, and protect your budget. If you want to document your building with millimeter accuracy or compare your as-built conditions to original plans Arrival 3D can help.